An animation of an axial compressor. The darker colored blades are the stators.

Schematic diagram showing the operation of a centrifugal flow turbojet engine. The compressor is driven via the turbine stage and throws the air outwards, requiring it to be redirected parallel to the axis of thrust.

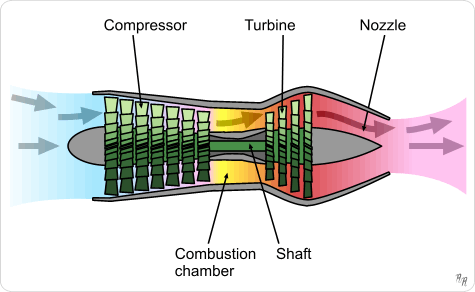

Schematic diagram showing the operation of an axial flow turbojet engine. Here, the compressor is again driven by the turbine, but the air flow remains parallel to the axis of thrust.

Air Intake.

Preceding the compressor is the air intake (or inlet). It is designed to be as efficient as possible at recovering the ram pressure of the air streamtube approaching the intake. The air leaving the intake then enters the compressor. The stators (stationary blades) guide the airflow of the compressed gases.

Compressor.

The compressor is driven by the turbine. The compressor rotates at very high speed, adding energy to the airflow and at the same time squeezing (compressing) it into a smaller space. Compressing the air increases its pressure and temperature.

In most turbojet-powered aircraft, bleed air is extracted from the compressor section at various stages to perform a variety of jobs including air conditioning/pressurization, engine inlet anti-icing and turbine cooling. Bleeding air off decreases the overall efficiency of the engine, but the usefulness of the compressed air outweighs the loss in efficiency.

Several types of compressor are used in turbojets and gas turbines in general: axial, centrifugal, axial-centrifugal, double-centrifugal, etc.

Early turbojet compressors had overall pressure ratios as low as 5:1 (as do a lot of simple auxiliary power units and small propulsion turbojets today). Aerodynamic improvements, plus splitting the compression system into two separate units and/or incorporating variable compressor geometry, enabled later turbojets to have overall pressure ratios of 15:1 or more. For comparison, modern civil turbofan engines have overall pressure ratios of 44:1 or more.

After leaving the compressor section, the compressed air enters the combustion chamber.

Combustion chamber

The burning process in the combustor is significantly different from that in a piston engine. In a piston engine the burning gases are confined to a small volume and, as the fuel burns, the pressure increases dramatically. In a turbojet the air and fuel mixture passes unconfined through the combustion chamber. As the mixture burns its temperature increases dramatically, but the pressure actually decreases a few percent.

The fuel-air mixture must be brought almost to a stop so that a stable flame can be maintained.

This occurs just after the start of the combustion chamber. The aft part of this flame front is allowed to progress rearward. This ensures that all of the fuel is burned, as the flame becomes hotter when it leans out, and because of the shape of the combustion chamber the flow is accelerated rearwards. Some pressure drop is required, as it is the reason why the expanding gases travel out the rear of the engine rather than out the front. Less than 25% of the air is involved in combustion, in some engines as little as 12%, the rest acting as a reservoir to absorb the heating effects of the burning fuel.

Another difference between piston engines and jet engines is that the peak flame temperature in a piston engine is experienced only momentarily in a small portion of the full cycle. The combustor in a jet engine is exposed to the peak flame temperature continuously and operates at a pressure high enough that a stoichiometric fuel-air ratio would melt the can and everything downstream. Instead, jet engines run a very lean mixture, so lean that it would not normally support combustion. A central core of the flow (primary airflow) is mixed with enough fuel to burn readily. The cans are carefully shaped to maintain a layer of fresh unburned air between the metal surfaces and the central core. This unburned air (secondary airflow) mixes into the burned gases to bring the temperature down to something a turbine can tolerate.

Source: Wikipedia.

No comments:

Post a Comment