A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can handle.

Bearing friction

Plain bearings are simply a hole of the correct shape containing the relatively moving part, and use surfaces in rubbing contact, often with a lubricant such as oil or graphite. They are very widely used. Particularly with lubrication they often give entirely acceptable life and friction.

However, reducing friction in bearings is often important for efficiency, to reduce wear and to facilitate extended use at high speeds and to avoid overheating and premature failure of the bearing. Essentially, a bearing can reduce friction by virtue of its shape, by its material, or by introducing and containing a fluid between surfaces or by separating the surfaces with an electromagnetic field.

By shape, gains advantage usually by using spheres or rollers, or by forming flexure bearings.

By material, exploits the nature of the bearing material used. (An example would be using plastics that have low surface friction.)

By fluid, exploits the low viscosity of a layer of fluid, such as a lubricant or as a pressurized medium to keep the two solid parts from touching, or by reducing the normal force between them.

By fields, exploits electromagnetic fields, such as magnetic fields, to keep solid parts from touching.

Combinations of these can even be employed within the same bearing. An example of this is where the cage is made of plastic, and it separates the rollers/balls, which reduce friction by their shape and finish.

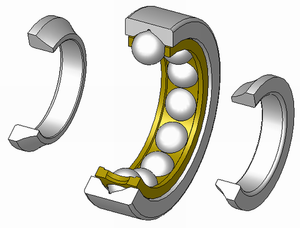

An example of a four-point contact ball bearing.

Creative Commons: Wikipedia